• Overview of Process Improvement: Understanding its significance and evolution.

• Fundamentals of Lean Management: Exploring the five core Lean principles.

• Lean Tools Overview: Introduction to essential Lean tools and their applications.

• Activity: Engage in a group exercise to identify waste in a given process using Lean

principles and create a value stream map based on case studies.

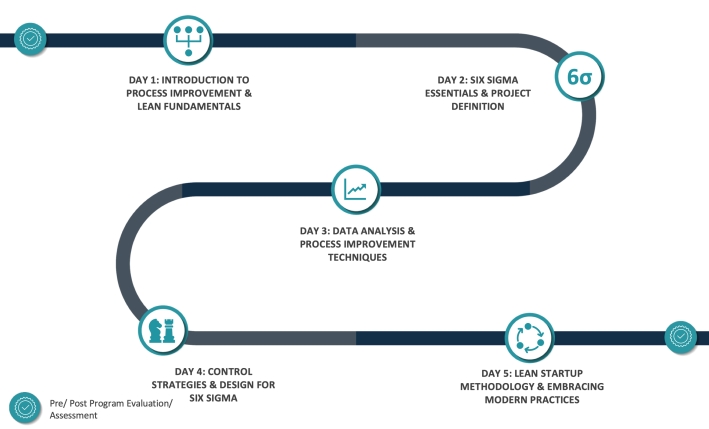

Day 2: Six Sigma Essentials & Project Definition

• Introduction to Six Sigma: Overview of the methodology and DMAIC framework.

• The Define Phase: Setting up a Six Sigma project, scoping, and goal setting.

• Metrics & Measurement: Understanding the importance of metrics in process

improvement.

• Activity: Workshop on defining a Six Sigma project, including drafting a project charter

and identifying key metrics for a hypothetical project.

Day 3: Data Analysis & Process Improvement Techniques

• The Measure and Analyse Phases: Data collection strategies and analytical techniques.

• Introduction to Statistical Tools: Basic and advanced tools for data analysis.

• The Improve Phase: Developing strategies for process improvement.

• Activity: Hands-on data analysis exercise using a case study, followed by brainstorming

improvement solutions in small groups.

Day 4: Control Strategies & Design for Six Sigma

• The Control Phase: Tools and techniques for maintaining improvements.

• Introduction to DFSS: Overview of Design for Six Sigma and the IDOV framework.

• Integrating Lean and Six Sigma: Exploring the synergies and benefits.

• Activity: Develop control strategies for sustaining process improvements. Introduction

to a DFSS project idea with group discussions on applying DFSS principles.

Day 5: Lean Startup Methodology & Embracing Modern Practices

• Lean Startup in Practice: Applying principles in startups and established businesses.

• Contemporary Practices in Process Improvement: Digital transformation, AI, and

machine learning in process improvement.

• Wrap-Up and Action Planning: Consolidating learnings and planning for application in

participants' work environments.

• Activity: Simulate the Lean Startup Build-Measure-Learn loop with a product/service

idea. Group presentations on how to incorporate modern process improvement practices in their organizations.

• Interactive Lectures: Delivered by seasoned industry professionals, the lectures cover the essentials of process improvement, drawing on a wealth of real-world examples and experiences. These sessions are crafted to provide depth and context to each methodology, from Lean management to Six Sigma and Lean Startup practices.

• Case Studies: Participants will delve into a selection of real-world case studies that showcase the application of process improvement strategies across various industries. These cases are instrumental in illustrating the tangible impact of these methodologies on operational efficiency and innovation.

• Group Discussions: The course promotes an environment of collaboration, leveraging the diverse experiences of participants. Group discussions are integral, encouraging the exchange of ideas, strategies, and problem-solving approaches, enriching the learning experience for all.

• Hands-On Exercises: To reinforce the concepts introduced in lectures, daily practical activities are embedded within the curriculum. These exercises challenge participants to apply their newly acquired skills in real-time, enhancing their competency in identifying, analyzing, and improving business processes.

• Feedback Sessions: Constructive feedback is a cornerstone of the learning process. Regular sessions provide participants with valuable insights from instructors and peers alike, enabling them to refine their understanding and approaches to process improvement.

• Scenario-Based Learning: Central to the course's methodology, each day features activities focused on specific, simulated scenarios that replicate the challenges encountered in process improvement roles. This immersive approach prepares participants to navigate complex business environments effectively, applying Lean, Six Sigma, and Lean Startup methodologies to drive meaningful change.

Benefits to Individuals

• Enhanced Skill Set: Individuals will gain comprehensive knowledge and practical skills in Lean, Six Sigma, and Lean Startup methodologies, enhancing their ability to drive process improvement within their organisations.

• Career Advancement: Mastery of process improvement practices significantly increases employability and opens up opportunities for career advancement in roles focused on operational excellence and efficiency.

• Problem-Solving Abilities: The course equips individuals with advanced problem-solving skills, enabling them to identify, analyze, and resolve inefficiencies in business processes effectively.

• Professional Development: Participants will receive certification upon completion, validating their expertise in process improvement and contributing to their professional growth and development.

• Networking Opportunities: Engaging with peers and industry experts during the course provides valuable networking opportunities, facilitating the exchange of ideas and experiences.

Benefits to Organisations

• Operational Efficiency: Employees skilled in process improvement methodologies can significantly enhance operational efficiency, leading to cost reductions and improved productivity.

• Innovation and Adaptability: Organizations benefit from having team members who can apply Lean Startup principles to foster innovation and adapt quickly to market changes.

• Quality Improvement: Implementing Six Sigma tools and techniques contributes to higher quality outputs, reducing errors and increasing customer satisfaction.

• Competitive Advantage: Skilled practitioners in process improvement can help organizations achieve a competitive edge by optimizing processes that contribute to faster delivery times and higher quality products or services.

• Culture of Continuous Improvement: Individuals trained in these methodologies can champion a culture of continuous improvement within their organizations, driving ongoing enhancements and efficiencies.

The course culminates in a scenario-based multiple-choice examination, designed to test the depth and application of your process improvement practices knowledge. Comprising 60 questions to be answered in 90 minutes, the exam will challenge you with real-world scenarios that require applying principles learned during the course. This format is intended to assess your ability to think critically and apply product management concepts in various situations, providing a comprehensive evaluation of your learning and readiness to excel in the field of product management.